Earthwise Water Systems™

Custom Water is Not a Pipe Dream - Reduce Downtime with Engineered Water

Benefits

- Improved processing efficiency

- Increased profitability

- Decreased water and energy use

- Increased sustainability

- Reduced maintenance

- Decreased downtime

- Promotion of health and safety

The Challenge

Water treatment program design is unique to each system. The goal of the program is to protect system equipment and piping from the highest temperatures and stress experienced,maintining the highest heat exchange coefficient. We design water treatment systems that can meet your most difficult heat exchange requirements.

Engineered Performance Fluid

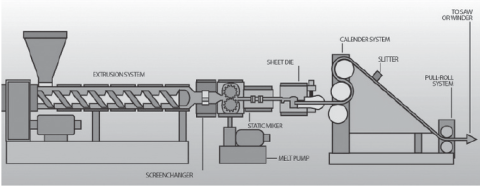

Engineered water is used in boiler water, cooling water, plastic extrusion and food processing applications. We design the water management program around the critical heat transfer areas. Ion exchange, membrane technology and chemical innovation are used to manipulate the properties of water.

EPF™ 4100 is an example of an engineered water specifically designed to cooling plastic extruder barrel zones. The barrel zone cooler on a plastic-extrusion machine experiences temperatures in excess of 500°F, at which point water vaporizes and corrosion and scale occur, plugging critical solenoid valves and shutting down production. As the temperature rises in the barrel, damage to the machine causes the loss of product and production time. Downtime is extremely costly. By providing consistent and reliable zone cooling, EPF™ 4100 prevents these adverse outcomes, protecting workers, capital equipment, the bottom line and the environment.

Click to view the EPF™ 4100 Brochure

EPF Case Study Highlights

A Midwestern plastic extrusion molding plant found significant savings in labor, replacement parts, equipment failures and production downtime when they implemented EPF 4100 in their 6 extrusion systems.

| Annual Costs | Before EPF 4100 | With EPF 4100 |

|---|---|---|

| Machine Maintenance | $27,000 | $20,000 |

| Scrap | $14,000 | $8,000 |

| Production Downtime | $115,000 | $13,000 |

| Total Impact of Cooling Zone Improvement | $156,000 | $41,000 |

Case History | ||

How Earthwise Environmental Can Help

Earthwise Water Systems™ is an innovative approach to managing industrial water systems. For applications with very challenging heat exchange requirements, the best solution lies in custom tailoring, or engineering, water properties for optimum performance.